The Art of Precision: Mastering the Industrial Counterbalanced Forklift

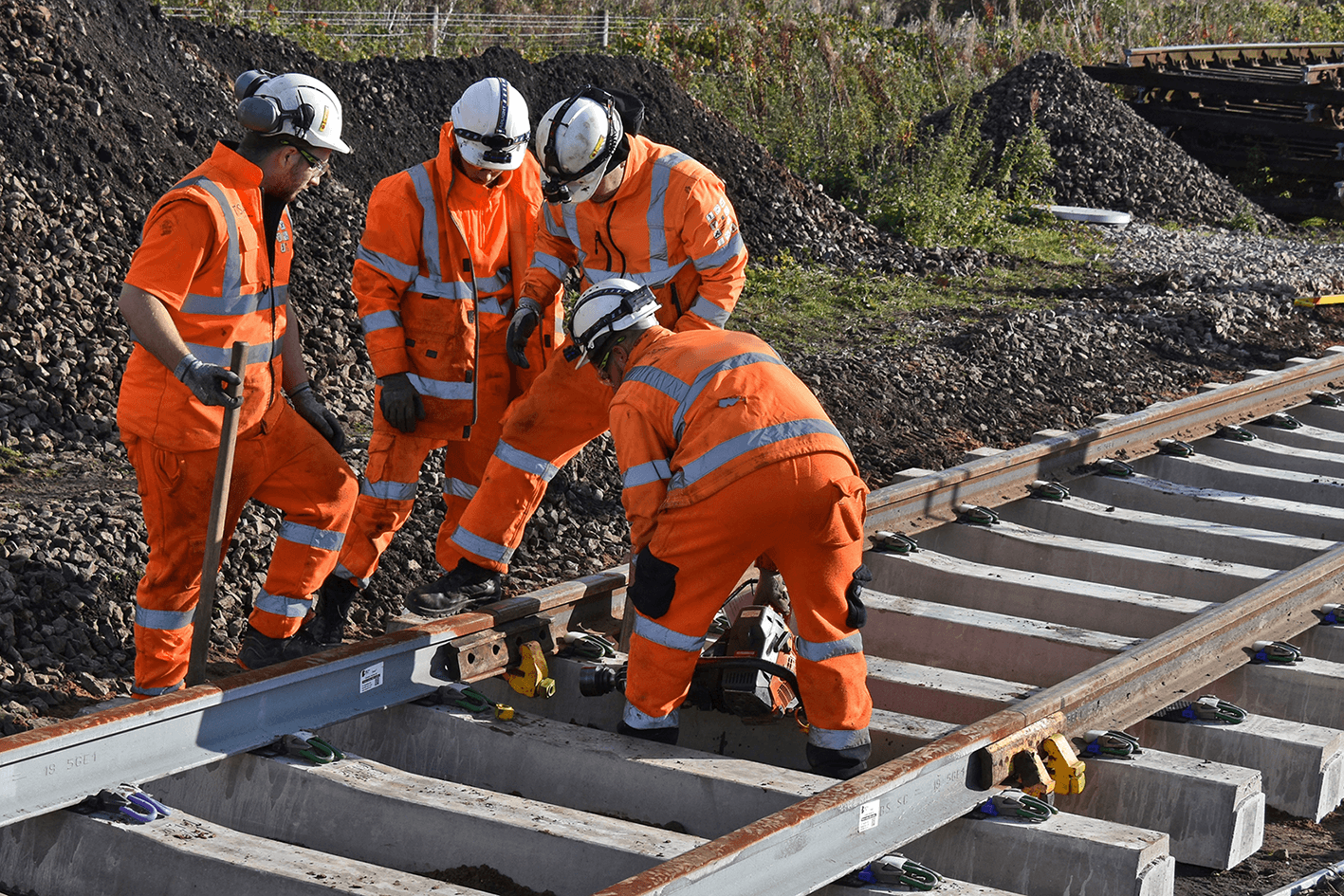

Welcome to the latest blog post from Training Lives, where we delve into the essential world of industrial counterbalanced forklifts.

A staple in the logistics and warehouse sectors, mastering these machines is pivotal for operational efficiency and safety.

Understanding Counterbalanced Forklifts

A counterbalance forklift is an industrial vehicle designed to carry and stack loads efficiently.

Its distinguishing feature is the counterweight at the back, which balances the load at the front, preventing the machine from tipping over.

These forklifts are versatile, capable of operating both indoors and outdoors, and can handle a broad range of weights, from 1.8T to 48T, depending on their design and size.

Key Features and Advantages

Versatility in Operation:

Counterbalanced forklifts can operate on different surfaces and environments, thanks to their pneumatic or cushion tires, making them suitable for varied operational settings.

Diverse Fuel Options:

These machines come in various fuel types, including LPG, petrol, diesel, and battery electric, allowing customization based on the operational environment and requirements.

Enhanced Safety:

The in-built counterbalance ensures stability, reducing the risk of tipping, a crucial factor when handling heavy or irregular loads.

Attachment Adaptability:

Adding different attachments enhances the functionality of counterbalanced forklifts, allowing them to handle various tasks beyond lifting and moving pallets.

Operational Considerations

Indoor vs. Outdoor Use:

While counterbalanced forklifts are adaptable to both settings, choosing the right tire type and fuel option is critical to optimize performance and safety in the given environment.

Load Handling:

Understanding the load capacity and how it’s affected by the mast’s distance from the load’s gravity center is vital for safe and effective operation.

Maintenance and Safety

Ensuring regular maintenance and understanding the key components, such as the mast, carriage, and tilt cylinders, is vital for the longevity and safe operation of the forklift. Training and awareness are crucial, as the proper operation of these machines requires knowledge of their mechanics and handling characteristics.

Conclusion

Mastering the industrial counterbalanced forklift is an art that combines knowledge, skill, and precision. By understanding the mechanics, capabilities, and safety protocols, operators can significantly contribute to the efficiency and safety of warehouse operations.

At Training Lives, we are committed to providing comprehensive Industrial Counterbalance FLT training and resources to empower individuals and organizations in harnessing the full potential of industrial counterbalanced forklifts.

Latest news, how to guides and more

The Comprehensive Guide to Counterbalanced Forklift Truck Training

The Comprehensive Guide to Counterbalanced Forklift Truck Training Welcome to Training Lives' in-depth guide on counterbalanced forklift truck training, a crucial element for anyone aspiring to become a proficient forklift operator. In this guide, we delve into...

Safety Protocols for Industrial Forklift Operations

Safety Protocols for Industrial Forklift Operations Ensuring safety during forklift operations is critical in any industrial setting. With a combination of best practices, adherence to regulations, and proper training, forklift-related accidents, which are often...

Mastering the Art of Forklift Operations

Mastering the Art of Forklift Operations: Why NPORS N001 is Essential In the dynamic world of industrial and construction environments, mastering forklift operations is not just about enhancing efficiency—it's about ensuring safety and compliance with industry...