Safety Protocols for Industrial Forklift Operations

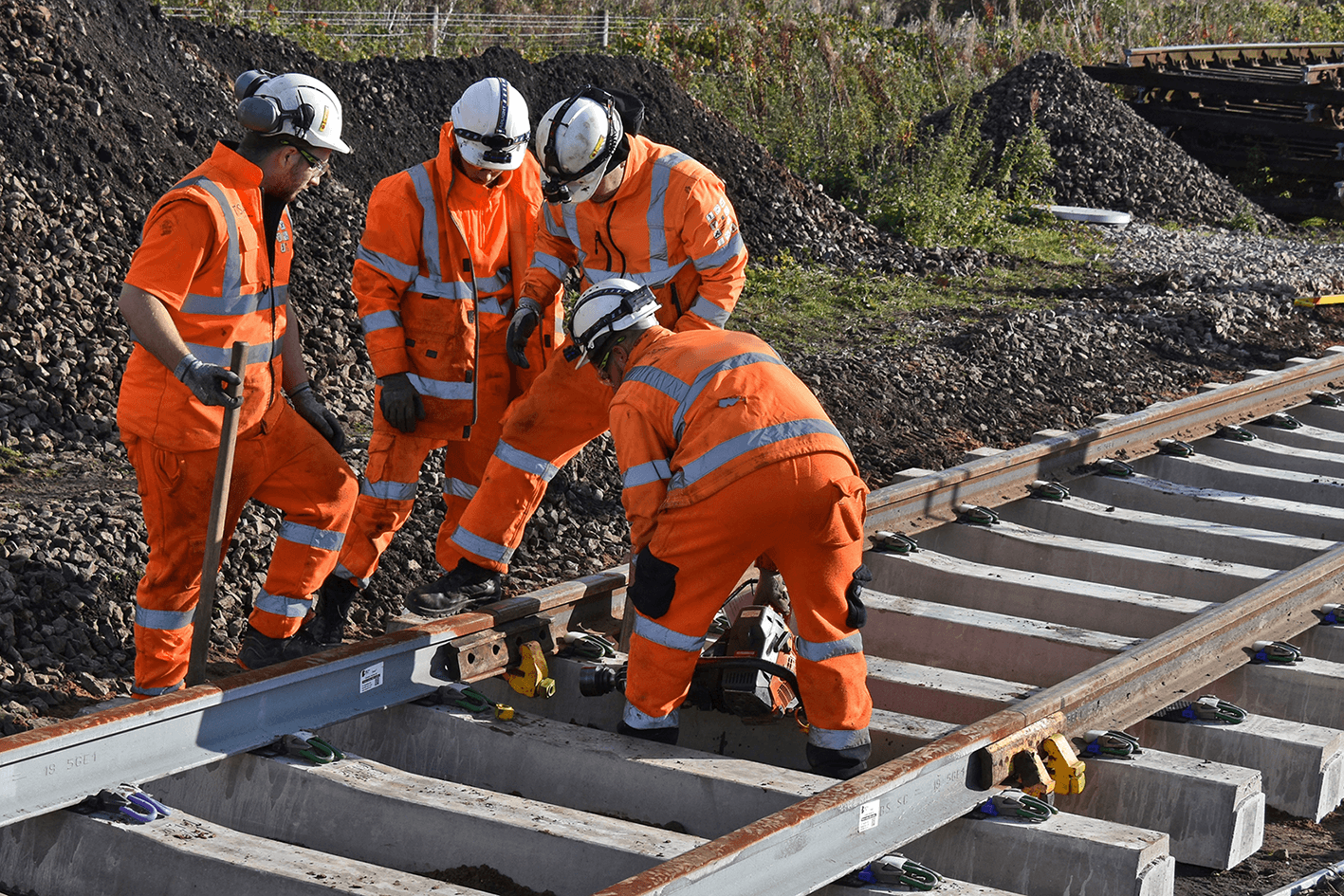

Ensuring safety during forklift operations is critical in any industrial setting. With a combination of best practices, adherence to regulations, and proper training, forklift-related accidents, which are often preventable, can be significantly reduced.

Below are essential safety protocols and guidelines based on industry standards and OSHA regulations to help maintain a safe environment during forklift operations.

Comprehensive Training and Certification

All forklift operators must undergo comprehensive training and certification to ensure they are proficient in handling the equipment safely. This training includes understanding forklift mechanics, learning proper operation techniques, and recognizing potential hazards.

Daily Inspections and Maintenance

Before each shift, operators should perform thorough inspections of the forklift to identify any potential issues that could lead to accidents or malfunctions. This includes checking tires, brakes, lights, and other critical components.

Proper Load Handling

Operators should be aware of their forklift’s capacity and avoid overloading, which can cause instability and increase the risk of tipping over. Ensuring that loads are stable and secure before moving is also vital.

Operational Best Practices

Forklift operators should adhere to operational best practices such as driving at safe speeds, avoiding abrupt maneuvers, and wearing seat belts. It’s also essential to maintain a clear line of sight and use spotters or mirrors in areas with limited visibility.

Environment Awareness

Understanding and being aware of the operating environment are crucial. This includes recognizing and respecting designated forklift zones, adhering to floor markings, and being mindful of pedestrian traffic.

Technology and Innovation

Leveraging technology, such as autonomous or remote-controlled forklifts, can enhance safety by reducing direct exposure to hazardous environments. However, these innovations come with their own set of safety protocols to ensure secure operation.

Emergency Preparedness

Operators should be trained in emergency response procedures, including what to do in case of an accident or mechanical failure. Knowing how to react promptly and appropriately can prevent injuries and minimize damage.

Forklift safety is a multifaceted issue that requires a concerted effort from operators, management, and the entire workplace community.

By implementing stringent safety protocols, providing ongoing training, and embracing technological advancements, workplaces can significantly reduce the risks associated with forklift operations and foster a culture of safety.

To get upto date on the safety protocols for industrial forklift operations contact us to book your course.

Latest news, how to guides and more

The Comprehensive Guide to Counterbalanced Forklift Truck Training

The Comprehensive Guide to Counterbalanced Forklift Truck Training Welcome to Training Lives' in-depth guide on counterbalanced forklift truck training, a crucial element for anyone aspiring to become a proficient forklift operator. In this guide, we delve into...

Mastering the Industrial Counterbalanced Forklift

The Art of Precision: Mastering the Industrial Counterbalanced Forklift Welcome to the latest blog post from Training Lives, where we delve into the essential world of industrial counterbalanced forklifts. A staple in the logistics and warehouse sectors, mastering...

Mastering the Art of Forklift Operations

Mastering the Art of Forklift Operations: Why NPORS N001 is Essential In the dynamic world of industrial and construction environments, mastering forklift operations is not just about enhancing efficiency—it's about ensuring safety and compliance with industry...